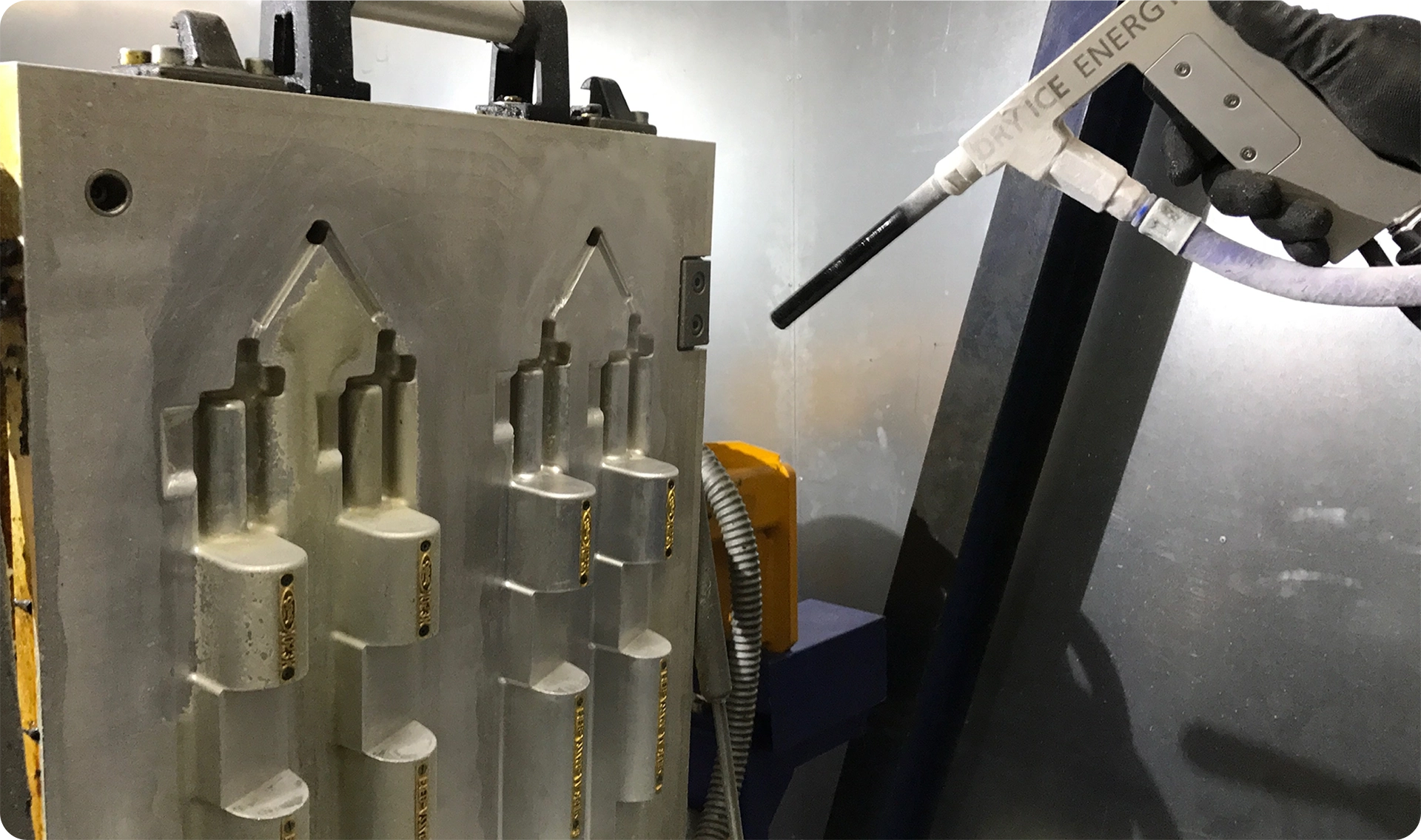

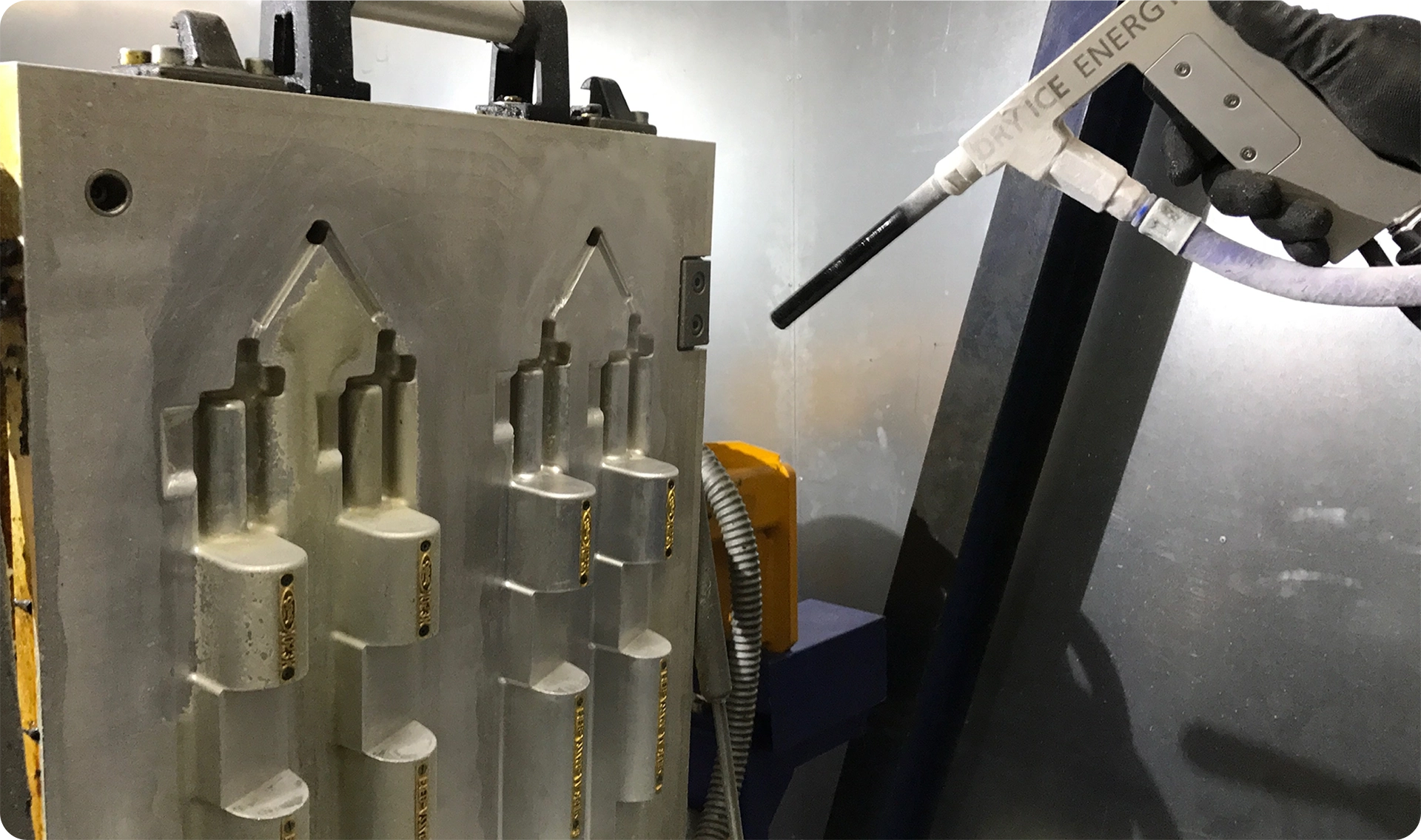

Mold cleaning in the plastics industry is often very time-consuming due to the complex structure of the tools and molds as well as the high quality requirements. Often the molds become scratched or their structure changes over time until they can no longer be used - which can quickly mean a five to six-figure new investment. Dry Ice Energy Thanks to the gentle cleaning, it not only offers faster cleaning without water and chemicals, but also extends the life cycles of the molds used.

The dry ice cleaning devices from Dry Ice Energy Weigh only 17 kg, are very mobile and require no electricity - the purchase costs are significantly lower than with conventional ones Dry ice blasting machines (€20.000 and more) and the low dry ice consumption (between 7 and 25 kg/h) makes the work very economical.

It can be cleaned during operation and the compact dry ice blasting device can be easily moved from mold to mold. Cleaning takes place during ongoing operation without the molds having to be removed or cooled down. This achieves extremely high flexibility and time savings in cleaning of over 40 percent. At the same time, production quality is improved because the ventilation of the tools is cleaned significantly better and scrap is reduced. The gentle cleaning significantly increases the service life of the tools. The cost of the chemical cleaning agents previously used and the one now used Dry ice are about the same height.

Application examples Dry Ice cleaning

in the Plastics industry

Advantages of dry ice blasting devices in maintenance

- Cleaning time reduced by 25-40 percent

- Cost-neutral use due to the elimination of aggressive chemicals

- Use in the running process without cooling the molds directly in the machine

- Special dry ice quality - extremely gentle on the surface

- Flexible use due to low weight (13-23 kg)

- Less rejects thanks to improved cleaning quality, even for complex shapes

Have we piqued your interest?

Contact Person

In Contact come

Dry Ice Energy GmbH

Wiebestrasse 36-37

10553 Berlin / Germany