Latest Posts

dry ice cleaning

from us Dry Ice Energy

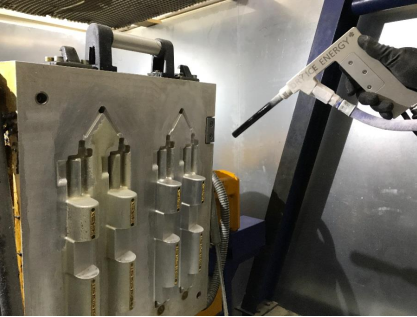

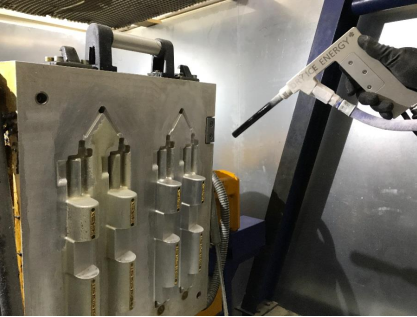

Optimization of tool and mold cleaning in the plastics industry with mobile and flexible dry ice cleaning in vacuum cleaner format.

Innovative compact dry ice cleaning enables flexible cleaning during operation and reduces cleaning time by 25 to 40 percent without chemicals and water.

Problems that traditional cleaning methods cause.

Often the molds become scratched or their structure changes over time until they can no longer be used - which can quickly mean a five to six-figure new investment.

Mold cleaning in the plastics industry is often very time-consuming due to the complex structure of the tools and molds as well as the high quality requirements and requires the time-consuming use of mechanical cleaning processes in combination with the use of chemical, aggressive and often health-hazardous cleaning agents.

“We have been looking into the alternative dry ice cleaning for our molds for a long time and have also received recommendations from our colleagues in the USA.”

Head of toolmaking at Technimark.

Dry ice as an alternative – impractical for many?

In addition, there are high acquisition costs of over EUR 20.000, high dry ice consumption and therefore high ongoing operating costs. Nevertheless, dry ice cleaning offers many advantages – it is not abrasive and requires no water or chemicals.

Dry ice cleaning has been discussed and used for some time as an alternative to manual chemical cleaning. However, the blasting devices currently available on the market are often very heavy and therefore unwieldy, extremely loud at times of over 120 db and require compressed air that often cannot be operated without adjustments to the compressed air lines and compressors.

The dry ice, which is accelerated by compressed air at a temperature of -79 degrees, increases its volume by 700 times when it hits the molds and thus removes dirt caused by release agents, oil, grease or outgassing without leaving any residue.

Dry-Ice-Energy: the revolution in cleaning dry ice

“We tested several providers and always had a problem with approval from occupational safety due to the high volume of the devices. We found what we were looking for Dry Ice Energy – a manufacturer of extremely compact dry ice machines, which impressed us with their easy and flexible handling and low noise levels.”

The dry ice cleaning devices from Dry Ice Energy weigh from 12kg, are very mobile and require no electricity - they are also very economical with an investment of less than EUR 8.000 and a low dry ice consumption of between 7 and 25 kg/h.

Cleaning without standing still: Dry-Ice-Energy makes it possible!

It can be cleaned during operation and the compact dry ice machine can be easily moved from mold to mold. Cleaning takes place during ongoing operation without the molds having to be removed or cooled down. This achieves extremely high flexibility and time savings in cleaning of over 40 percent. At the same time, production quality is improved because the tool vents are cleaned significantly better and scrap is reduced. The gentle cleaning significantly increases the service life of the tools.

“At first we had concerns as to whether cleaning would be possible with the machines Dry Ice Energy which pushes dirt into the cavities of the tools - however, this has not been confirmed. We were impressed by the easy handling and the high cleaning quality.”

The costs for the chemical cleaning agents used previously and for the dry ice now used are approximately the same. Also when maintaining the

Tools that are completely dismantled result in a significantly simplified way of working and enormous potential for efficiency.

Where to get high-quality dry ice from?

Dry Ice Energy is also a producer of high-quality dry ice and supplies its customers in flexible quantities with a delivery time of just one day. This means that the customer is always provided with fresh, high-quality dry ice for the cleaning processes.

The loss due to sublimation of the dry ice is kept to a minimum, which also contributes to the economic efficiency of the process. Dry ice cleaning with Dry Ice Energy represents an effective, environmentally friendly and, above all, cost-neutral way of cleaning molds, with which a significant increase in productivity is only possible through changed cleaning technology. At the same time, the quality of the products is increased, the durability of the tools is significantly increased and the exposure of employees to harmful chemical cleaners is reduced.

Have we piqued your interest?

Contact Person

In Contact come

Dry Ice Energy GmbH

Wiebestrasse 36-37

10553 Berlin / Germany